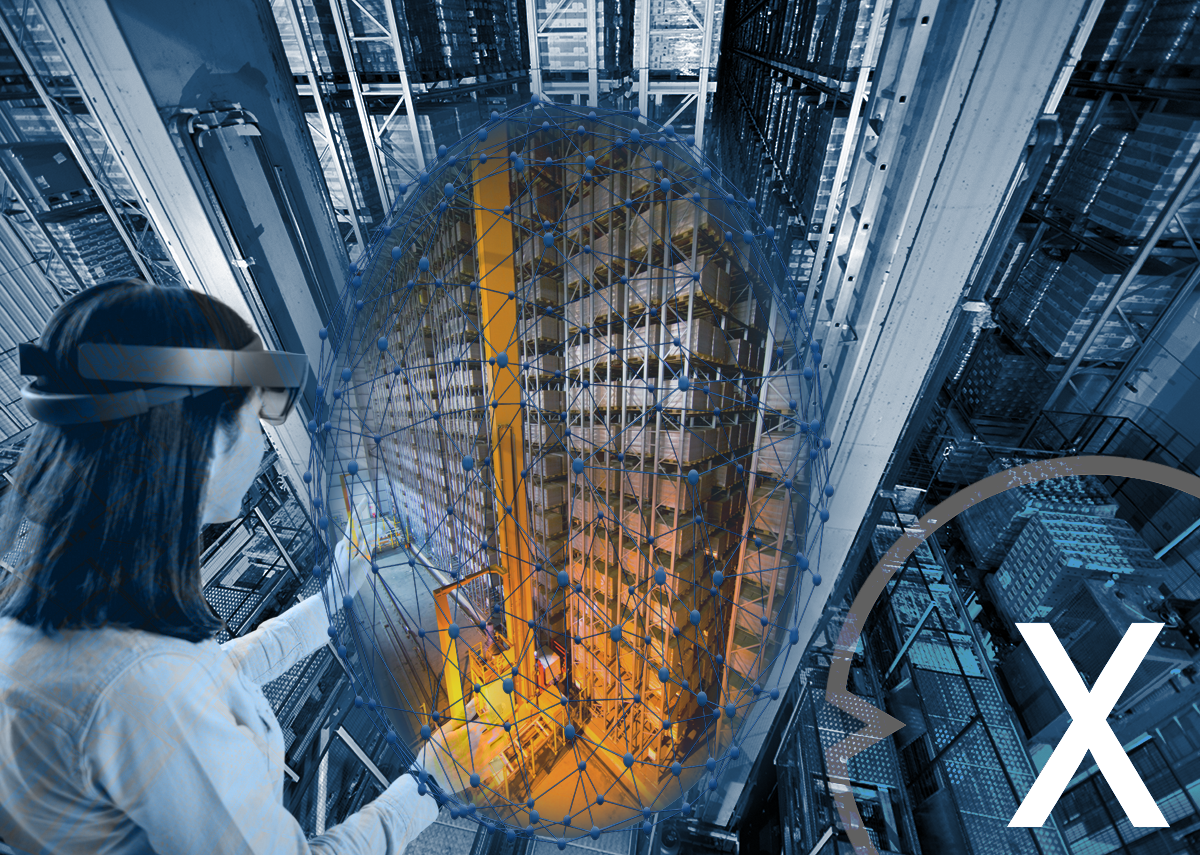

ASRS – Automated Storage and Retrieval System: Automated storage and retrieval system (RGB) | Metaverse Marketing – Image: Xpert.Digital

The intelligent stacker crane (RSG) of the future: Efficient storage with Metaverse and 2D matrix codes

Warehousing and management plays a central role in many industries and companies. Efficient processes and optimal use of resources are crucial for the success of a company. In this context, the intelligent stacker crane (RBG) of the future is becoming increasingly important. With advanced technologies such as the Metaverse and 2D matrix codes, the RBG promises a revolutionary improvement in automated storage and retrieval system (ASRS) storage.

The RBG combines the performance of the latest automation technology with the innovative possibilities of Metaverse and 2D matrix codes. The ASRS technology enables the RBG to automatically and efficiently store and retrieve goods in high-bay warehouses. The RBG uses special gripper arms to precisely move pallets, containers or other storage containers and place them in the correct positions. This automated storage offers numerous advantages such as improved space utilization, optimized inventory management and increased efficiency in picking.

A key feature of the intelligent RBG of the future is the integration of the Metaverse. The Metaverse is a virtual environment in which people and digital objects can meet and interact interactively. In the context of the RBG, the Metaverse enables the use of XR technologies such as Virtual Reality (VR) and Augmented Reality (AR). This opens up completely new possibilities for controlling and monitoring the RBG. For example, warehouse employees can virtually immerse themselves in the high-bay warehouse and control the SRM from the device's perspective. This not only makes operation easier, but also enables a quicker response to disruptions or bottlenecks in warehouse operations.

The use of 2D matrix codes also plays a crucial role in connection with the RBG. These special codes are placed on storage containers, products or shelves and contain important information such as product identification, storage location or specific instructions. The RBG is equipped with sensors and readers that scan the 2D matrix codes and process the information in real time. This allows the SRB to automatically identify the correct containers, determine the storage locations and carry out the required tasks efficiently. The use of 2D matrix codes not only optimizes warehouse operations, but also enables precise tracking and traceability of goods and inventory.

In addition to increasing efficiency, the intelligent RBG of the future also offers other advantages. By automating warehouse processes, human errors are minimized, resulting in greater accuracy and reliability. The RBG can work around the clock, resulting in maximum utilization of the warehouse and extending operating hours. In addition, the RBG enables integration into a higher-level warehouse management system that provides real-time data on inventory, movements and performance. This enables better planning and decision-making based on current information.

Overall, the intelligent RBG of the future promises optimal automated storage with the integration of Metaverse and 2D matrix codes. The combination of ASRS technology, XR technologies and advanced sensors takes warehousing to a new level. Businesses can benefit from improved efficiency and productivity gains, leading to optimized inventory management and a competitive advantage. The continuous development of these technologies will make the intelligent RBG even more powerful and open up new opportunities for the intralogistics industry.

Our Industrial Metaverse configurator

Just try out our universally applicable (B2B/Business/Industrial) Metaverse configurator for all CAD / 3D demo options:

Xpert (B2B/Business/Industrial) Metaverse configurator for all CAD / 3D data can be used on all devices, one platform!

Suitable for:

ASRS 2.0: Revolutionary warehouse automation with XR technology and advanced sensor technology

Automated warehousing has made enormous progress in recent years and with the ASRS 2.0 (Automated Storage and Retrieval System) a revolutionary development in the field of warehouse automation is imminent. This innovative system combines groundbreaking technologies such as XR (Extended Reality) technology and advanced sensor technology to significantly increase efficiency and accuracy in warehouse environments.

XR technology plays a central role in ASRS 2.0. Extended Reality includes Virtual Reality (VR), Augmented Reality (AR) and Mixed Reality (MR). By using VR, warehouse employees can immerse themselves in a virtual environment, for example to conduct training or simulate complex tasks. AR allows employees to overlay digital information into their physical environment in real time, which is extremely useful when picking or putting goods away. With MR, real and virtual objects can interact, making it possible to insert virtual models of storage shelves or products into the physical environment, for example to determine the optimal storage location.

Another crucial factor in ASRS 2.0 is the advanced sensor technology. By using sophisticated sensors such as optical sensors, laser scanners or RFID technology, the system can capture precise information about the warehouse environment and the products stored. These sensors enable the ASRS 2.0 to collect accurate data about the location, condition and quantity of goods. This allows the system to make optimal decisions to optimize warehouse operations, minimize errors and ensure safety.

The ASRS 2.0 offers a number of advantages over traditional warehouse automation systems. By using XR technology, warehouse workers can complete tasks faster and more efficiently. For example, they receive visual instructions right in front of their eyes, which speeds up picking and minimizes errors. The combination of XR technology and advanced sensor technology enables precise location and identification of products, resulting in improved inventory management and reduced errors.

In addition, the ASRS 2.0 enables flexible and customizable warehouse configuration. By using virtual models, warehouse layouts can be simulated and optimized to make optimal use of space and avoid bottlenecks. The sensor technology allows the system to precisely track the movements of goods and monitor inventory in real time. This means that bottlenecks or excess capacity can be identified early and appropriate measures can be taken.

Security also plays an important role in ASRS 2.0. Through precise sensor technology and the integration of XR technology, potential dangers can be identified and avoided. For example, virtual safety zones can be set up to protect employees from dangerous machines or collisions. The sensors continuously monitor the warehouse environment and can react to irregularities at an early stage to prevent accidents.

The ASRS 2.0 promises revolutionary warehouse automation with a combination of XR technology and advanced sensor technology. By streamlining workflows, reducing errors, and improving efficiency, this advanced approach is expected to transform enterprise warehousing. Companies should carefully consider the capabilities of ASRS 2.0 and consider how they can integrate these innovative technologies into their warehouse environments to gain competitive advantage and increase efficiency.

Top Ten: The ten best-known manufacturers and companies of automated storage and retrieval systems (RGB) or Automated Storage and Retrieval System (ASRS)

Daifuku

Daifuku is a global leader in material handling systems and logistics solutions. They also offer ASRS systems and RGBs aimed at optimized warehousing and efficient processes.

Dematic

Dematic is a global leader in automated logistics solutions that develops and supplies ASRS systems for various industries. Their broad product portfolio includes storage and retrieval machines with innovative technology.

Swisslog

Swisslog is a renowned manufacturer of ASRS systems and RGBs. They offer tailor-made solutions for warehouse automation and are known for their high quality and reliability.

SSI Shepherd

SSI Schäfer is an international provider of logistics solutions and also produces automated storage and retrieval machines. They offer a variety of ASRS systems tailored to customers' individual requirements.

Vanderlande

Vanderlande is a global provider of automated material handling systems and also offers ASRS systems and RGBs. Their solutions are designed for efficient and optimized warehousing.

Meager

Knapp is an Austrian company that specializes in the development and production of innovative logistics solutions. They also offer automated storage and retrieval systems and ASRS systems for various industries.

TGW

TGW is a provider of intralogistics solutions and specializes in providing automated storage solutions. Their product range also includes ASRS systems and RGBs for efficient warehousing.

viastore

viastore is a leading manufacturer of automated storage and logistics systems. They offer customized ASRS solutions that meet the individual requirements of their customers.

Witron

Witron is a German manufacturer of automated logistics solutions and has many years of experience in developing ASRS systems. They also offer RGBs for efficient warehousing and picking.

Bastian Solutions

Bastian Solutions is an American provider of automated material handling systems and ASRS solutions. They offer customized solutions for warehouse automation and are known for their technical expertise.

The new dimension of warehousing: XR technology and sensor technology with 2D matrix codes in the automated storage and retrieval machine

Warehousing has reached a new dimension by integrating XR (augmented reality) technology and sensor technology with 2D matrix codes in automated storage and retrieval machines. This innovative combination enables more efficient and precise management of goods in warehouses and logistics centers.

XR technology uses virtual reality (VR) and augmented reality (AR) to create an immersive experience and improve interaction between humans and machines. In the case of automated storage and retrieval machines, XR technology can provide the operator with real-time visual information. By wearing VR glasses, the operator can see a virtual image of the warehouse while controlling the stacker crane. This allows for more precise navigation and positioning of the device as the operator receives precise information about the location of the goods and the available storage locations.

Sensor technology with 2D matrix codes complements XR technology by enabling precise identification and tracking of goods in the warehouse. 2D matrix codes are special codes that encode information in the form of black squares on a white background. They can be printed on individual products or packaging and contain a unique identifier for each item. Automated storage and retrieval machines are equipped with sensors that can read and interpret these codes. This allows the devices to precisely locate, collect and store goods in the correct storage locations.

The combination of XR technology and sensor technology with 2D matrix codes offers a number of advantages for warehousing. First, it improves accuracy and efficiency in inventory management. Operators can precisely control the stacker crane and select and store the right items with minimal effort. By integrating the 2D matrix code sensors, errors in goods identification and placement can be reduced, resulting in optimized inventory management and less rework.

Second, XR technology enables intuitive and immersive training of operators. New employees can learn the stacker crane in a simulated environment and gain hands-on experience before beginning actual operations. This improves safety and reduces potential damage to goods and equipment.

In addition, XR technology offers the ability to collect and analyze data about inventory. By integrating sensors, information about the condition of goods, inventory availability and storage space requirements can be recorded. This data can be used to optimize inventory strategy and predict demand.

It is important to note that the introduction of XR technology and sensor technology with 2D matrix codes in automated storage and retrieval systems requires a certain investment. The necessary hardware components such as sensors and VR glasses must be purchased and the corresponding software developed or adapted. Additionally, employee training is required to realize the full potential of these technologies.

➡️ The combination of XR technology and sensor technology with 2D matrix codes opens up a new dimension in warehousing. It improves efficiency, precision and safety when managing goods in automated storage and retrieval machines and enables optimized inventory management. As technology advances, this innovative combination is expected to become even more refined and widely adopted in the logistics industry.

The fully automated alternative? The better choice?

Fully automated stacker cranes offer a number of advantages over narrow aisle trucks and reach trucks that make them an attractive choice for warehousing.

Higher storage capacity

Fully automated storage and retrieval machines can offer higher storage capacities than narrow-aisle forklifts and reach trucks. Thanks to their vertical design, they can reach shelves at greater heights, making optimal use of the available space in the warehouse. This is particularly beneficial for businesses with limited floor space as they are able to store more goods in a small space.

More efficient use of space

Thanks to their precise control and the ability to make tighter curves, fully automated storage and retrieval machines enable optimal use of the available storage space. Compared to narrow-aisle forklifts, which require a wider aisle, stacker cranes can utilize narrower aisles, making more efficient use of space. This leads to higher storage density and better utilization of the storage space.

Greater speed and productivity

Fully automated storage and retrieval machines are generally faster than narrow-aisle forklifts and reach trucks. You can move along the shelf aisles at high speed and store and retrieve goods efficiently. This increases productivity and reduces lead times, which is particularly beneficial in busy warehouse environments.

Lower error rate

The fully automated nature of the stacker cranes minimizes human errors. The precise control and positioning of the devices, combined with the use of sensor technologies, ensures precise and reliable storage and retrieval of goods. This reduces misplacement and minimizes the risk of damage to the goods.

Improved workplace safety

Since the fully automated storage and retrieval machines work without direct operator operation, the risk of accidents for employees is significantly reduced. There is no risk of collisions with other vehicles or injury when loading or unloading goods. This improves workplace safety and creates a safer working environment for staff.

Automated processes

Fully automated storage and retrieval machines can be seamlessly integrated into automated warehouse management systems. This enables automation of processes such as inventory tracking, goods tracking and management. The devices can be connected to warehouse management software and barcode scanning technologies to ensure smooth and efficient material flow.

➡️ However, it is important to note that fully automated storage and retrieval machines can also pose some challenges. The acquisition and operating costs are generally higher than with conventional types of forklifts. In addition, the implementation of such systems requires extensive planning and adaptation of the warehouse infrastructure.

➡️ Despite these challenges, fully automated storage and retrieval machines offer a variety of advantages that lead to improved efficiency, productivity and safety in warehousing. They are ideal for companies with high inventory turnover, limited space and the need for automated processes.

The Smart Logistics Future of Goods Handling: The Next Generation Automated ASRS

The future of goods handling in the logistics industry will be shaped by the next generation automated ASRS (Automated Storage and Retrieval System). This groundbreaking technology promises efficient and precise warehousing as well as a smooth flow of materials in warehouses and logistics centers.

The next generation automated ASRS features a number of innovative features. One of them is the integration of artificial intelligence (AI) and machine learning. By processing large amounts of data, intelligent algorithms can identify patterns and trends to improve warehouse optimization. For example, the system can automatically move the most frequently requested items to the front of the warehouse to speed access and reduce picking times.

Another feature of the next generation automated ASRS is the use of robotics. Robotic arms can be used to take over the storage and retrieval of goods. These robots are able to scan the shelves, identify the correct items, and grab and move them precisely. This achieves high accuracy and speed when handling goods.

In addition to robotics, next-generation automated ASRS enables the use of autonomous vehicles. These vehicles can navigate the warehouse aisles and transport goods between different storage areas. By avoiding bottlenecks and using the available space efficiently, material flow is optimized and a higher throughput rate is achieved.

Another important feature of the next generation automated ASRS is the integration of IoT (Internet of Things). Sensors and smart devices can be connected to the system to collect real-time data about inventory levels, temperature and humidity conditions, and other relevant information. This enables comprehensive monitoring and control of the warehouse in order to identify and resolve bottlenecks or potential problems at an early stage.

The benefits of next-generation automated ASRS are many. Firstly, it leads to a significant increase in efficiency and productivity. Automating inventory handling minimizes human errors, reduces operational costs and shortens lead times. This allows companies to make their supply chains faster and more efficient.

Second, next-generation automated ASRS improves inventory accuracy and precision. By using robotics and AI-controlled algorithms, errors when storing and retrieving goods are minimized. This contributes to optimized inventory management and better control over inventory levels.

In addition, the next generation automated ASRS contributes to increased security. The use of robotics and autonomous vehicles reduces the risk of accidents and injuries caused by human intervention. The system can also implement security protocols to control access to the warehouse and protect goods from theft or damage.

➡️ The Smart Logistics future of goods handling is being revolutionized by the next generation automated ASRS. As technology advances and AI, robotics, and IoT are integrated, warehouses and logistics centers will be able to make material flow more efficient, precise, and secure. Companies that invest in this innovative technology will gain a competitive advantage and take their warehousing to new levels.

Logistics consulting and logistics optimization

Logistics consulting and logistics optimization by external experts for automated storage and retrieval systems (RBG) and automated storage and retrieval systems (ASRS) offers a variety of advantages for companies.

Expertise and experience

External logistics experts have extensive specialist knowledge and many years of experience in the planning, implementation and optimization of automated storage and retrieval machines and ASRS systems. They know the latest technologies, best practices and trends in the industry and can use this knowledge to develop tailored solutions for any company.

Objective assessment: External experts offer an objective assessment of a company's current logistics processes and structures. Through a thorough analysis, you can identify weak points and uncover potential for improvement. This objective perspective is often crucial in identifying inefficient processes and initiating appropriate optimization measures.

Customized solutions

Every company has different requirements for its logistics processes. External logistics experts can develop individual solutions that are specifically tailored to a company's needs and goals. They take into account factors such as warehouse size, product types, inventory volume, delivery times and other relevant parameters to ensure optimal configuration of RBGs and ASRS systems.

Increased efficiency: By working with external experts, companies can optimize their logistical processes and improve efficiency. This includes reducing search times, maximizing storage capacity, optimizing storage and retrieval processes, and minimizing errors and bottlenecks. By implementing efficient RBGs and ASRS systems, companies can save time, resources and costs.

Technology selection and integration

The market for automated storage and retrieval machines and ASRS systems is diverse and constantly evolving. External experts can help companies select the right technology that best suits their specific needs. You have insight into the various providers, their product portfolios and can make an informed decision. In addition, they help seamlessly integrate the new technology into the company's existing infrastructure.

Continuous improvement

Logistics consulting and optimization are not one-off activities, but rather a continuous process. External experts can support companies in regularly monitoring, evaluating and improving their logistics processes. By implementing key performance indicators (KPIs) and conducting regular audits, companies can measure and continuously optimize their logistics performance.

➡️ Working with external logistics experts for automated storage and retrieval systems and ASRS systems can be a smart investment. It enables companies to benefit from expertise, experience, objective assessments, tailored solutions, efficiencies, technology selection and integration, and continuous improvement. By optimizing their logistics processes, companies can become more competitive, reduce costs and ensure smooth operations.

Xpert.plus-industry expert, here with its own 'xpert.digital industrial hub' in the field of mechanical engineering of over 1,000 specialist contributions

Xpert.Plus is a project from Xpert.Digital. We have many years of experience in supporting and advising on storage solutions and in warehouse optimization, which we bundle in a large network under Xpert.Plus.

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital – Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital – www.xpert.solar – www.xpert.plus