Published on: January 8, 2025 / Update from: January 8, 2025 - Author: Konrad Wolfenstein

180 billion US dollars mark: 2024 was the year of AI - 2025 could be the year of cobots and robotics - Image: Xpert.Digital

The year of the cobots: Intelligent helpers on the rise in everyday life and business

Technology boost robotics: The global potential of 180 billion dollars

After the year 2024 was largely characterized by rapid progress in the field of artificial intelligence (AI), a new technological surge is emerging for the coming year 2025: the age of robotics could now finally dawn. As AI sharpens the minds behind the machines, intelligent robots are poised to capture an estimated $180 billion global market. Collaborative robots, or cobots for short, play a key role in this promising development. Their unique abilities to work safely and efficiently with human workers are currently revolutionizing the world of work and opening up unimagined possibilities. This development not only promises enormous economic potential, but also profound changes in almost all areas of life.

How intelligent robots, and especially cobots, are conquering a $180 billion market

The ability of robots to independently learn new skills and adapt to changed environments marks a turning point in robotics thanks to advanced AI algorithms. These “learning” robots are no longer limited to repetitive tasks in standardized environments. You can master complex processes, make decisions and even interact with people in a way that previously seemed science fiction. In particular, cobots that were specially developed for cooperation with humans change the way we work.

The global robotics market is currently experiencing significant growth and is forecast to reach over $180 billion by 2030. Experts from the analysis company Grand View Research assume an average annual growth rate of an impressive 20 to 25 percent. This immense potential is fueled by a variety of factors that are driving a real revolution in the industry and beyond. A key driver of this growth is the increasing acceptance and implementation of cobots in a wide variety of industries.

Suitable for:

Driving forces of the robotics market and the special role of cobots

1. Increasing demand for automation and flexibility through cobots

The unstoppable trend towards automation is one of the main drivers of the robotics boom. Companies in almost all industries are increasingly recognizing the need to automate complex and repetitive processes to increase efficiency while reducing operating costs. While conventional industrial robots often operate in confined areas and are optimized for high-volume, standardized tasks, cobots offer a flexible alternative. They can be used directly next to human employees without the need for complex protective fences. This ability for direct human-robot collaboration enables production processes to be designed more efficiently, as humans and machines can ideally complement each other. Cobots often take on ergonomically unfavorable or monotonous tasks, relieve the burden on human colleagues and enable them to concentrate on more demanding and creative activities. This flexibility makes cobots particularly attractive to small and medium-sized businesses (SMEs), which often do not have the resources for large-scale automation projects.

2. Integration of artificial intelligence (AI) and the intelligence of cobots

The fusion of artificial intelligence and robotics represents a paradigm shift. AI gives robots “intelligence”, which enables them to go beyond mere programming. AI-supported robot can perceive their surroundings, analyze data, learn from them and make decisions independently. This ability for adaptation and independent learning opens up completely new fields of application for robots. Cobots also benefit enormously from this development. Through AI, for example, you can better interpret human gestures and intentions, dynamically adapt to changing work processes and even support with complex assembly tasks. This “intelligent collaboration” makes Cobots a valuable partners in production environments in which flexibility and adaptability are decisive. Advanced sensors and image processing systems enable cobots to record their surroundings in detail and to recognize potential dangers, which further increases security in human-robot interaction.

Suitable for:

3. Industry 4.0, collaborative robotics and the vision of the connected factory

The concept of the “Industry 4.0” or the intelligent factory is massive to demand for collaborative robots. These robots are designed in such a way that they can work safely and efficiently with human workers without the need for elaborate fences. Cobots often take on ergonomically unfavorable or repetitive tasks, relieve human colleagues and enable more flexible and efficient design of the production processes. The integration of cobots into the production lines enables companies to use the advantages of automation without having to do without the flexibility and the specialist knowledge of human employees. This symbiotic cooperation between man and machine is a core aspect of Industry 4.0 and an essential factor for increasing operating efficiency. Cobots are not only independent automation solutions, but can also be seamlessly integrated into networked production environments. You can collect, analyze and communicate data with other machines and systems, which leads to a comprehensive optimization of the production processes.

4. Labor shortages, offshoring and the attractiveness of cobots

An increasing problem in many industrialized countries, especially in the USA and Europe, is the lack of qualified workers. This bottleneck affects many industries and forces companies to look for alternative solutions. Cobots offer an attractive option here because you can take on tasks for which no or difficult workers can be found. Especially in areas with physically exhausting or monotonous activities, cobots can offer valuable support and increase the attractiveness of these jobs. In addition, the trend towards offshoring, i.e. the relocation of production locations abroad, could at least partially be reversed by using robots and especially cobots. If companies can automate and flexible their production processes, even in smaller lot sizes, they can remain competitive, even if the wage costs are higher in Germany. The possibility of “researing” production processes through cobots, that is, moving back to Germany, is becoming increasingly interesting for many companies because it enables shorter supply chains and greater flexibility.

5. Advances in sensors, actuators and the safety of cobots

Continuous advances in sensors and actuators are crucial for the performance of modern robots and especially for the safety of cobots. Increasingly sophisticated sensors enable cobots to perceive their surroundings more precisely and detect the presence of people. Force-torque sensors, optical sensors and tactile sensors play a crucial role in avoiding potential collisions or minimizing the force in the event of a collision. More powerful and precise actuators enable smooth and controlled movements, which further increases safety when working directly with people. Compliance with strict safety standards and norms is a central aspect in the development and use of cobots in order to minimize the risk of injuries.

6. Falling costs of cobots and the democratization of robotics

Although the acquisition costs for robots can still be a significant investment, prices for cobots have tended to decrease in recent years and are expected to continue to decrease. On the one hand, this is due to scale effects in production and on the other hand because of the further development of the technologies, which lead to cheaper solutions. The falling costs make cobots accessible to a wider range of companies, including small and medium -sized companies, which have so far been detached from automation. The easier programming and commissioning of cobots compared to conventional industrial robots also helps to reduce the total costs and to “democratize” the robotics.

Market development and forecasts in detail and the role of cobots

The numbers speak for themselves: the industrial robotics market, which traditionally accounts for the largest share of the robotics market, will grow from $14.86 billion in 2022 to an impressive $30.47 billion in 2030. This corresponds to a compound annual growth rate (CAGR) of 9.39 percent. A significant portion of this growth is due to the increasing demand for cobots, which enable more flexible and collaborative automation solutions.

The market for service robotics is developing even more dynamically. This area includes robots that are not primarily used in industrial production environments, but in a variety of other fields of application, such as healthcare, logistics, hospitality or private households. Cobots are also playing an increasingly important role in this segment, as their ability to safely interact with people in these environments makes them particularly suitable. The service robotics market is expected to grow from $19.08 billion in 2023 to a significant $62.35 billion in 2030. The forecast average annual growth rate of 18.4 percent underlines the immense potential of this segment, in which cobots will make a significant contribution.

Global investment in robotics is estimated to be well over $180 billion by 2030. This huge sum demonstrates investors' confidence in the future growth potential of robotics and associated technological innovations, with a significant portion of these investments going towards the development and implementation of cobot solutions.

Europe's role in the global robotics market and the pioneering role in cobots

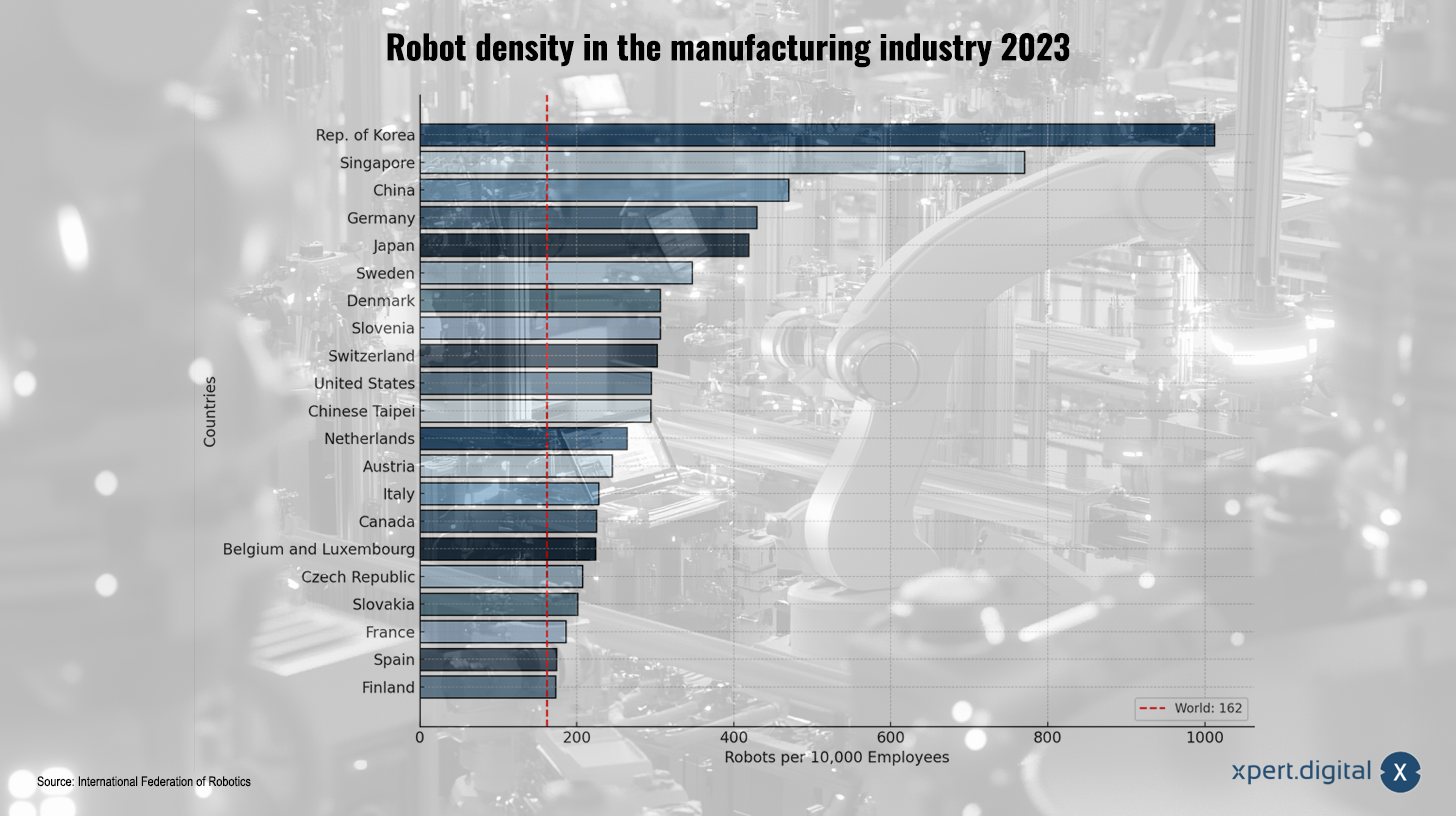

Europe, and Germany in particular, plays an important role in the global robotics sector and is at the same time a pioneer in the development and use of cobots. Germany is considered one of the leading nations in robotics and automation technology. This is not least due to the country's strong automotive industry, which has traditionally been a large buyer of industrial robots and is now increasingly relying on the flexibility and efficiency of cobots.

Increasing demand for robotic automation, particularly in the automotive, mechanical engineering and electrical industries, is driving market growth in Europe. European companies recognized the potential of cobots early on and are increasingly investing in their integration into their production processes. Increasing investments in the robotics industry, both from government and private sources, are also contributing to the positive development. Countries like Germany and Sweden are largely responsible for market growth in Europe. They have a well-developed research landscape, innovative companies and a qualified specialist base. In addition, the European Union specifically promotes the development and use of robotics and especially cobots through various funding programs and initiatives in order to strengthen the competitiveness of European industry.

Suitable for:

Outlook and future opportunities with cobots in focus

The integration of artificial intelligence into robotics opens up fascinating new possibilities, especially in the area of self-learning systems. Cobots will increasingly be able to not only perform repetitive tasks more efficiently, but also learn from their experiences and continually improve their performance. This enables the use of cobots in specialized industries and in complex environments that require high cognitive skills and adaptability. Future generations of cobots are expected to be even more intuitive to use, have improved sensor technology and cognitive abilities and can be integrated even more closely into work processes.

This development promises not only significant economic growth, but also groundbreaking technological innovations in a wide range of sectors. In manufacturing, for example, AI-supported cobots can optimize production processes, improve quality assurance and enable more flexible production lines. In the healthcare sector, cobots can assist with patient care, support rehabilitation and even carry out precise tasks in operating rooms. In logistics, cobots can be used in picking, packaging and internal transport.

There are also a variety of possible uses for cobots in the services sector. From service robots in hotels and restaurants that take on tasks such as serving food or serving, to assistant robots in retail that advise customers and present products, to cobots in agriculture that help harvest and care for plants - the possibilities are almost unlimited.

Robotics, and especially collaborative robotics, will play a key role in shaping our future in the coming years. Advancing automation and human-robot collaboration will change the world of work, create new job profiles and change existing ones. It is therefore crucial that society, politics and business develop strategies together to make optimal use of the opportunities offered by robotics while at the same time overcoming the potential challenges. This includes, for example, training workers to prepare them for the changing demands of the labor market, as well as developing ethical guidelines for the use of AI and robotics and promoting the acceptance of cobots in the world of work.

The year 2025 could actually be the year in which robotics, and especially cobots, make their breakthrough and realize their full potential. The combination of advanced AI, innovative hardware, increasing demand for flexible automation and growing awareness of the benefits of human-robot collaboration is creating a dynamic environment that makes robotics and cobots one of the most important technologies of the 21st century. The intelligent and collaborative revolution has just begun.

Suitable for: